Your sales team is on the phone with a contractor who needs 200 linear feet of 6-foot privacy fencing. They need to know what’s available right now. But your inventory system shows pipe footage, not actual pieces. And half your stock is in the outdoor yard, tracked on a clipboard. Sound familiar?

Most fencing distributors are still running on QuickBooks or Sage with Excel workarounds. The tools that got you to $5 million can’t get you to $20 million. But here’s the problem: most ERP systems don’t map to fencing operations either.

There’s a better way. ERP configurations which are built specifically for how fencing distributors and manufacturers actually operate.

Why Fencing Companies Hit a Wall with QuickBooks and Excel

QuickBooks handles basic financials, but it can’t track inventory the way fencing requires. Indoor yard vs. outdoor yard? Multiple locations? Material transformations after cutting? QuickBooks wasn’t built for that.

So Excel becomes the workaround for everything. Quotes live in spreadsheets. Inventory tracking is manual. Delivery schedules exist on paper or in someone’s head. Nothing connects, and nothing talks to each other.

It’s a mess. You’re entering the same data twice; your controller is losing their mind over month-end; the numbers still don’t add up; and reconciliation takes days instead of hours, with no single source of truth. Your team spends more time managing systems than managing the business.

The problem isn’t that your team isn’t working hard enough. It’s that you’re using tools that weren’t designed for distribution and manufacturing complexity.

What Makes Fencing Operations Different

Generic ERP vendors will tell you they can configure their system for any industry. And technically, they can. But that means you’re paying for months of discovery while consultants learn your business. You’re explaining what a puppy panel is. You’re teaching them why pipe cutting creates inventory tracking nightmares.

Fencing operations face specific challenges that generic implementations overlook.

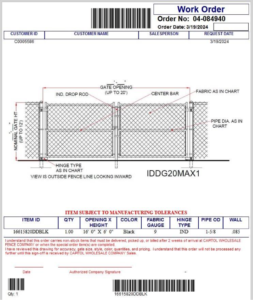

Pipe Cutting and Material Tracking

Let’s talk about the 24-foot pipe problem. You chop it into a 16 and an 8 for a rush job. On paper? You’re good. But inside your ERP, that 24-footer still exists as a ghost. Or worse, the system tells you that you have ’24 feet’ of pipe, but neglects to mention it’s now in two useless pieces for the next guy who needs a full rail. When your ‘total footage’ looks right but your yard is empty, your inventory reports aren’t just wrong, they’re fiction.

This isn’t a minor inconvenience. It means your inventory variance reports are meaningless. Job costing is inaccurate because you can’t allocate material costs correctly. And month-end reconciliation turns into a multi-day exercise in frustration.

The solution is disassembly tracking that records material transformations with proper cost allocation. When that 24-foot pipe becomes two smaller pieces, the system knows. You see exactly what sizes you have after cutting, not what you started with.

Delivery Scheduling Without Field Service

Most ERPs try to fit all deliveries into a cookie-cutter mold, treating your delivery drivers like HVAC technicians. If you need full installation tracking, crew scheduling, job progress, and time on site, that capability is available. But if you’re primarily focused on trucking schedules and delivery logistics, there are pre-built custom reports for exactly that: truck capacity, stop sequencing, and delivery windows without the overhead of a full field service module.

What works is a custom scheduler built on standard dashboard tools. i-Tech developed this truck scheduling solution in partnership with fencing distributors, designed around how they actually manage deliveries. You can track multiple trucks, see capacity at a glance, and manage stops with a tool built specifically for this industry.

Inventory Theft and Shrinkage

Let’s be honest: things ‘walk’ out of the outdoor yard. If a pick list can be deleted or ‘adjusted’ with a few keystrokes after the truck leaves, you don’t have an inventory system; you have a suggestion box. Without a permanent, locked-down audit trail, you’re basically just guessing why your counts are off by 5% at the end of the month.

The fix is permanent audit trails. Automatic pick list tracking creates records that can’t be deleted. You know who picked what, and when. When something doesn’t add up, you have a trail to follow.

Multi-Location Inventory Visibility

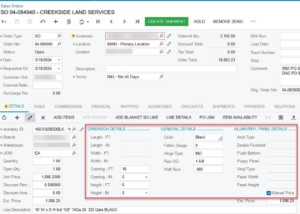

Your sales team is on the phone with a customer. They need to know if you have the product in stock. However, your inventory system displays items one at a time, and they must check each location separately.

Meanwhile, the customer is waiting. And if your rep provides them with incorrect information, you’ve either lost a sale or created a delivery issue.

Custom inventory inquiries let you view all inventory across all locations on a single screen. Not item-by-item lookups. Not switching between warehouses. One view that shows what’s available, where it is, and whether it’s in the indoor warehouse or the outdoor yard.

ERP That Speaks Your Language

These aren’t theoretical features or promises about what could be built. These configurations exist today and are based on real-world ERP implementations in fencing businesses. They exist because other fencing companies requested them, and they’re now ready to deploy.

Disassembly tracking that handles pipe cutting. Shipment calendars that manage delivery routes without field service headaches. Audit trails that create accountability. Inventory views that show your whole operation at once.

Keith Ford, President of Eagle Fence Distributing, put it this way: “We feel we can add a warehouse or branch in a 30-day window or shorter, because we have the financial backbone all set up and ready to go.”

That’s what happens when your ERP actually fits your business. Growth becomes a configuration change, not a six-month implementation project.

Getting There Without the Pain

ERP implementations have a reputation. Months of discovery. Consultants who don’t understand your business. Go-live dates that slip. Budget overruns.

That reputation exists for a reason. But most of that pain comes from starting with a blank slate. When consultants have to learn your industry during implementation, everything takes longer and costs more.

When configurations already exist for your industry, you’re not starting from scratch. The screens are built. The workflows are tested. The edge cases have already been identified and resolved by the companies that came before you.

That’s the difference between an implementation that takes months and one that takes weeks. Users get hands-on access early. You launch with core functionality and optimize over time. And you’re not paying consultants to learn what a chain link tension band is.

What This Looks Like in Practice

Back to that sales rep on the phone with the contractor. With the right system, they see real-time inventory across all locations, including what’s in the outdoor yard. They know exactly which pipe sizes are available after cutting. They can commit to a delivery window because the shipment calendar shows truck capacity.

The contractor receives an answer in seconds rather than several minutes. Your rep closes the sale instead of promising to call back. And when the order ships, there’s an audit trail from pick list to delivery.

That’s not a fantasy. It’s what fencing distributors are doing today with ERP configured for their operations.

Ready to see how it works? Visit Fence and Perimeter Security – i-Tech Support to learn more about Acumatica Cloud ERP configured for fencing operations or schedule a demo to see the screens in action.