Acumatica Manufacturing

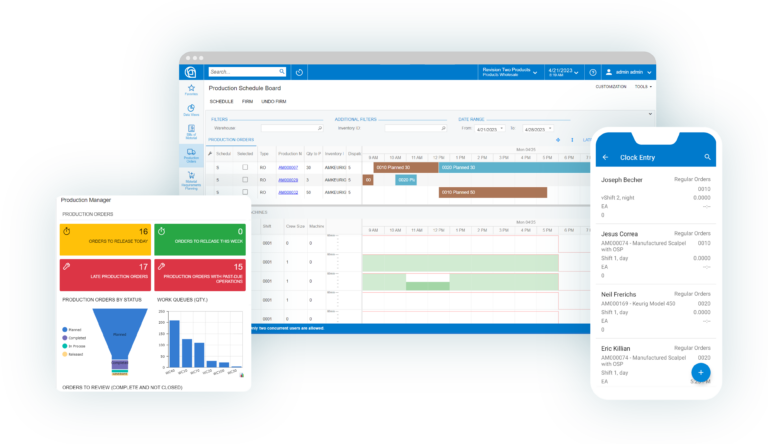

The Acumatica Manufacturing edition helps you manage every aspect of your of your operations in one place with unlimited user access

- Connect data, systems, and processes on a single platform

- Meet schedules with time-phased MRP and finite scheduling

- Reduce cycle times for faster fulfillment and improved quality

Fan-Array Maker Q-PAC’s Explosive Growth Supported by Acumatica Manufacturing ERP

Industries

Manufacturing, Cross industries

Headquarters

Elkton, Florida USA

- Implemented a single, connected, modern manufacturing platform that helps it scale and grow

- Improved customer service, providing a seamless connection between its project configurator QUIPS and Acumatica Manufacturing, which allows data to flow engineering, manufacturing, shipping, and invoicing

- Gained inventory management with visibility into inventory and production costs used to calculate project profitability while also reducing inventory carrying costs

- Automated reporting, saving time while gaining insights on which to make better decisions

- Gained Bill of Materials functionality that sped production and improved revision history access

- Replaced manual data entry with automated processes, saving time

Piro Zisi, Supply Chain Manager

Q-PAC Systems, Inc.

Challenges

Spun out of Mass HVAC in 2019, Q-PAC makes custom Plug-and-Play fan systems for commercial HVAC systems designed for air handling retrofits and OEMs. Its success stems from offering a disruptive product that is delivered and installed quickly. Each fan array is custom-built to customer specifications, with straightforward installation and various features for optimizing facilities.

The company sells its fan systems to office buildings, universities, airports, hospitals, and entertainment venues such as stadiums and arenas. Because each venue has different requirements, Q-PAC developed its own ordering software, QUIPS, which automates the selection and design process according to a customer’s facility operation and space specifications.

“The company operated within Mass HVAC for eight years before being spun out in 2019,” says Kevin Van Dyke, Chief Financial Officer.

“We were incubated inside a company that built air handlers, and we were the fan component,” he says. “We have a very innovative idea of using EC fans and assembling them in a kit-oriented way for new air handlers and retrofit opportunities, allowing us to repair and replace fans in the field.”

Each fan array is shipped as a kit with every component needed to install, assemble, and begin operating in the shortest possible time. With its patent-pending Quick Connect Box and wiring system, installation time has been reduced by 75%. Additionally, its optional BACnet-compatible controller enables a system to operate independently without any field-installed controls.

Q-PAC operates on the principle that “Fan systems should be easy; we are easier.”

“When it comes to the HVAC component we provide, we are probably the fastest in the industry in terms of installation,” says Luis Burgos, Director of Operations. “We offer a simple service: our products are easy to select, install, and service.”

Customers seem to appreciate Q-PAC’s easy-to-install fan systems. “We are averaging around 30% growth,” says Van Dyke. “Actually, it’s been 40% growth since starting as a standalone company. We’ll do close to $32 million this year.”

Difficult to Operate on Spreadsheets

When Q-PAC began operating as a standalone company, it relied on QuickBooks and Excel spreadsheets to manage production and inventory. This approach was tedious, cumbersome, often outdated, and prone to error—anything but efficient for a fast-growing startup.

“We didn’t really know our costs accurately at all,” explains Luis Burgos, Director of Operations. “We didn’t have part numbers, and most visibility on sales orders was through Excel files. Our operations were very task-oriented, and it was extremely difficult to keep track of order statuses. We barely even had part numbers.”

Without part numbers, executives lacked critical insights into inventory and project costs, making it challenging to quote projects accurately. The fragmented, basic systems made it difficult and time-consuming to process engineering changes or assemble bills of materials. Forecasting was also a challenge.

“We would ship something, and at year-end, we could look at the macro view,” says Kurt Thomas, Director of Marketing. “But we had no idea what our individual job gross margins were. With QuickBooks, we couldn’t dive that deep or link all our inventory. Plus, we were using so many different systems and Excel sheets that integrating them just didn’t make sense.”

The difficulty in assessing product profitability was further complicated by the custom nature of Q-PAC’s fans and the range of configurations customers required. To simplify the ordering process for customers, Q-PAC developed its custom software, QUIPS, which automates fan system selection and design based on the client’s specifications. The software covers over 4,000 parts, allowing flexibility and customization.

Q-PAC’s rapid growth, along with the limitations of manual work and disconnected systems, prompted the search for better solutions. “We reached the maximum potential of Excel to run a business,” says Burgos. “We found clever ways of using Excel and macros, but eventually, it just wasn’t sustainable.”

“The order volume was increasing significantly, and we weren’t operating efficiently,” adds Nick Tulip, Director of Technology. “With more orders, we either needed to hire more people or faced challenges scheduling the work.”

ERP Solution

Acumatica Manufacturing Edition

Connecting its QUIPS ordering system was Q-PAC’s top priority for a new ERP system. Q-PAC also wanted a cloud-based solution with multi-region support, scalability, and flexibility for customizing unique processes. “We didn’t want to adapt to a tool,” says Luis Burgos, Director of Operations. “We wanted to have a great tool with a good base that we could modify and customize for our use.”

Q-PAC evaluated Microsoft Dynamics, Odoo, and Oracle NetSuite before learning about Acumatica. They narrowed the list to Dynamics and Acumatica, ultimately choosing Acumatica for its unlimited user pricing, open API, and ease of use. Acumatica Manufacturing provided a single source of truth and the flexibility to integrate third-party applications.

“In Acumatica, you could see the integration capabilities that were exposed and available,” says Nick Tulip, Director of Technology. “And it became a no-brainer. Acumatica had some things we hadn’t even considered but realized we might need. The open API was the driving factor for us, and price was a significant factor. Everybody else had a user-per-seat license, which was expensive, but Acumatica offered unlimited users and was transaction-based,” he explains.

Initially, Q-PAC considered being an all-Microsoft shop. However, the enterprise-grade pricing of Dynamics and its complex implementation, which seemed overly complicated for a small startup, led them to reconsider. “I thought it would be an expensive experience, and if we failed to integrate external applications at that cost, it just didn’t make sense,” says Tulip. From a technical perspective, several executives agreed that Acumatica had everything Q-PAC needed to integrate and operate effectively.

“Once I learned more about Acumatica’s structure, the architecture behind the data pages, and how all the data is interconnected, I realized it would be incredibly easy to use and customize. We could view the data we needed and make it accessible for others through various inquiries,” Burgos adds.

Customer Success

As a startup, Q-PAC worked closely with I-Tech Solutions, Inc., its integration partner, to create new workflows. “We needed to set up our customers, business accounts, customer accounts, and other items,” says Tulip.

After everything was configured, Q-PAC moved over two years of data from multiple spreadsheets. “The transition process to Acumatica involved understanding different concepts like sales orders, bills of materials, vendors, inventory, stock items, and non-stock items to configure the endpoints that allowed us to port data over,” Tulip says. “It was actually quite smooth.”

Outcome

Automated Processes Save Time

Q-PAC now has instant access to a single record of information that used to take days to locate and compile—if it could even be found among numerous spreadsheets. Reports can now be generated in real-time with accurate data, giving executives a daily view of company performance rather than waiting weeks or months. Faster access to critical information allows Q-PAC to operate more efficiently and quickly adapt to market changes.

“Previously, the information was spread out; nobody knew what the latest information was, and finding it across different Excel files was very challenging,” says Luis Burgos, Director of Operations. “Thanks to Acumatica and our integrations, we get daily reports instantly, and monthly reports just two or three days after month-end. Having access to data anywhere, anytime, is key.” Burgos also appreciates that he can access customized dashboards on his smartphone from any location. “I mainly use it for our dashboard just to know how the week is going and what’s been produced,” he says.

Improved Inventory and Production

Q-PAC now imports design specifications from its QUIPS system directly into Acumatica, which automates the process of creating manufacturing requirements and work orders for subassemblies that ultimately roll up into a final assembly. Acumatica provides visibility so everyone can see whether components are in stock and what capacity is needed for a project. This enables Q-PAC to accurately assess inventory and production costs, helping executives calculate project profitability correctly.

“There are no more Excel files and no more errors,” says Nick Tulip, Director of Technology. “Previously, I had to manually transcribe orders into a spreadsheet and use search features to track order status,” says Randall West, Operations Manager. “Now, I can open a window to check an order’s status without spending 45 minutes searching. We can actually track what we can do now.”

Order status was often just a guess previously. “In terms of personal productivity, Acumatica probably saved me years of my life,” says West. “There’s a lot of time saved in inventory management, and now (the shop floor) has confidence that when they start an order, we’re not stalled for weeks waiting for a part we didn’t realize we needed.”

Acumatica provides the inventory forecasting and management that Q-PAC previously lacked. “We haven’t missed or skipped an order due to running out of components in a long time,” Burgos says.

Piro Zisi, Supply Chain Manager, notes that Acumatica has greatly reduced the time needed to access essential data. “I receive data on vendor on-time delivery, inventory, dollar amounts per item, types based on components, and stock levels, all updated in real-time on a dashboard,” he says. “The data uploads instantly, allowing me to focus on key issues and objectives. Having Acumatica as our ERP system provides real-time visibility across our organization, enabling us to make faster strategic decisions and enhancing collaboration across departments.”

Accurate Bill of Materials

Austin Pleasants, Product Engineering Manager, says Acumatica has given Q-PAC bill of materials (BOM) information they previously didn’t have. “We can now handle different product revisions, ensure production is following the right order, and compare it to the revision to check for differences.”

With Acumatica, design changes happen faster, and BOM is far more accurate. “Every job we handle is different,” Pleasants explains. “Every order has unique dimensions and arrangements, so our BOMs are different for each project. The open API lets us integrate our CPQ with Acumatica, creating a customized BOM for each order and grouping products and stock items as needed to match exactly what the customer wants.”

More Efficient Warehouse

Q-PAC is reorganizing its warehouse with multiple internal locations for item inventory and adding a support section to improve understanding of item use for customer orders and support tickets. Inventory is also being reconfigured to be closer to workstations, reducing the time needed to pick parts.

Additionally, Q-PAC has streamlined its shipping processes, providing the logistics manager with advance production completion data and shipment preparation details. This data is also shared with accounting for timely invoicing.

Alongside QUIPS, Q-PAC integrated Velixo Reports for advanced financial reporting and EBizCharge for credit card processing. The company plans to automate customer notifications for order milestones to boost customer satisfaction and experience.

Fast-Growing Manufacturer

Transitioning from a small operation with simple processes to a standard manufacturer, Q-PAC now fully understands the value of structured workflows, including using part numbers and tracking items from work-in-progress to final stages. “Acumatica has taught us how to operate efficiently and focus on processes that are crucial to success,” says West.

Burgos anticipates that Acumatica will support Q-PAC in ramping up production by five to ten times if necessary. “I don’t think Acumatica will ever be a limitation. Our data visibility is excellent, and we have a scorecard that shows daily, monthly, and year-to-date performance.”

Most importantly, Burgos says, “It makes our life much easier.”

Acumatica Manufacturing Edition Overview

See Acumatica How Acumatica Manufacturing Edition Works

ERP for Steel Pipe & Tube Suppliers

Experience full visibility in all units of measure common to the industry and supercharge your pipe supply operation with our industry-specify Cloud ERP solution.

powered by

Pipe Serialization

Inventory and logistics Tracking

Quality Records Management

Comprehensive Yard Management

Digitize Your Business Operations

Leverage the power of Acumatica with exclusive features designed to meet the unique needs of the OCTG industry.

-

Streamlined Operations

-

Integrated Inventory

-

Cost-Effective Growth

-

Enhances QMS

-

Field Service Management

Rapid Field Service Growth Demands Flexible, Affordable ERP

Industries

Apps Replaced

Sage

Headquarters

Headquarters in Houston, TX, with additional locations in Texas and Ohio

- Gained a high-value, affordable foundation that can handle rapid growth

- Gained transparency into operations, finance and inventory

- Streamlined operations and processes

- Avoided $175,000 in user-fee costs and about $250,000 in customization charges

- Acquired foundation to scale operations including field services

Yuri Dorovskikh, IT Manager

OFS International

OFSi Deploys Acumatica ERP Customer Success

OFSi provides premium products essential to the oil and gas industry, particularly for horizontal shale drilling. The company also offers services such as pipe inspection, pipe storage, accessories, field services, and rig returns. Known globally for its pipe threading expertise, OFSi also manufactures premium couplings.

Following an acquisition, it quickly became clear that the inherited Sage MAS 90 financial system lacked basic accounting functions, and its inventory system was not integrated with accounting. OFSi’s accounting and operational systems and processes needed to be completely rebuilt. There was no way to track sales orders, as most customers were invoiced only after a sale was completed. Inventory levels were based solely on what was visible in the yard.

“Invoicing was based on manual, paper-based work orders and carbon copies,” explains Yuri Dorovskikh, OFSi IT Manager. “If we invoiced a customer, retrieving all the paperwork related to that order was extremely hard and time-consuming. The sales process lacked transparency because invoicing was done after the fact, without creating sales orders. Even worse, the field services invoicing process was paper-based and sent to the main office before an invoice could be created and sent to the customer.”

In 2014, OFSi initiated a project to upgrade its accounting system from MAS 90 to Sage 100.

Over the years, OFSi expanded by acquiring several companies, resulting in three subsidiaries. Incorporating these new business units into Sage 100 proved difficult due to software limitations. OFSi realized it needed a modern, integrated ERP system to operate effectively.

After evaluating Epicor, JobBOSS, Sage, and SAP, the team chose Acumatica. Its unlimited user licensing model promised a savings of approximately $175,000 in user fees compared to Sage, and its open, adaptable platform offered easy integration with third-party systems.

ERP Solution

Implementation Challenge: Cultural Change

“As we build the business from purely a service company to a manufacturing and full solution provider, we needed more than just an inventory system,” says Yuri Dorovskikh, OFSi IT Manager. “Acumatica gives us the capability to manage purchase orders, available raw materials, and manufacturing modules, providing accurate for-sale inventories, including all associated costs.”

Dorovskikh persuaded top management to implement Acumatica in a newly acquired division as a test case to demonstrate its potential for the entire company, including several planned acquisitions.

Initially, the biggest challenge was encouraging OFSi employees not only to adopt new business practices but also to become comfortable with new technology. “It was about changing how we do business.”

OFSi purchased the on-premises version of Acumatica and implemented the Manufacturing, Inventory, Financial, and Field Service modules—the last of which is tailored for companies that repair products or equipment at customer locations.

The company has also integrated third-party solutions, including Office 365 and Microsoft PowerBI. “Anything Acumatica can provide, we want it,” Dorovskikh says. “We are planning to build on it as our foundation.” He also notes that he received approval to implement Acumatica at a cost slightly over a quarter of what other ERP vendors estimated.

Outcome

Managers with correct permissions now have full transparency into OFSi’s financial operations across its four entities. “Now we can analyze late customer payments, identify the biggest customers at any moment, and track our inventory,” says Yuri Dorovskikh, OFSi IT Manager. “We didn’t have this information before.”

“Managers can now drill down within Acumatica and see where a specific number is coming from instead of asking accounting to locate it,” he adds. OFSi has around 300 employees, with about 80 using Acumatica.

OFSi has significantly reduced invoicing time—from 21 days to same-day processing. Acumatica introduced transparency into their systems and quickly provides all related information for specific jobs or customers.

100 Percent Revenue Growth

“Acumatica has allowed OFSi to increase sales 100 percent year over year,” says David Green, vice president of operations. He notes that Acumatica’s flexible, full-featured software saved OFSi approximately $250,000 in consulting fees that other ERP solutions would have required to modify software to fit OFSi’s practices.

OFSi’s competitive advantage lies in its full-service package of pipes, couplings, premium connections, accessories, and field services. To deliver this suite with high levels of customer service, OFSi needed an accurate ERP system to fulfill customer orders from request to fulfillment within two weeks, which Acumatica enables.

Incorporating an MES (Manufacturing Execution System)

OFSi is in its fourth phase of Acumatica implementation, a customized initiative to manage the buying, selling, and monitoring of pipes and related services.

The company must capture and trace specific parameters about its pipes to ensure high-quality service. It created a program that links each pipe order and its attributes to a bar code that can be tracked throughout its usage, with Acumatica integrating all this data.

“Everything has to be traceable because if anything goes wrong at the customer location, we need to know how to resolve it,” Green explains. Dorovskikh adds, “Only Acumatica could allow us to integrate all of this information.”

Ease of Audit

“OFS International, LLC recently completed a financial statement audit under the guidelines of the Public Company Accounting Oversight Board, and Acumatica was integral to its success,” says Erica Howard, Senior Accountant. “We audited several years simultaneously, switching ERP systems to Acumatica mid-audit. The improvement in data collection, representation, and archiving that Acumatica offers versus our previous ERP was noticeable, facilitating transparency in record-keeping crucial for our data archiving and financial representation. Future audits will be more streamlined thanks to Acumatica’s data retention and presentation capabilities.”